March 14th, 2023

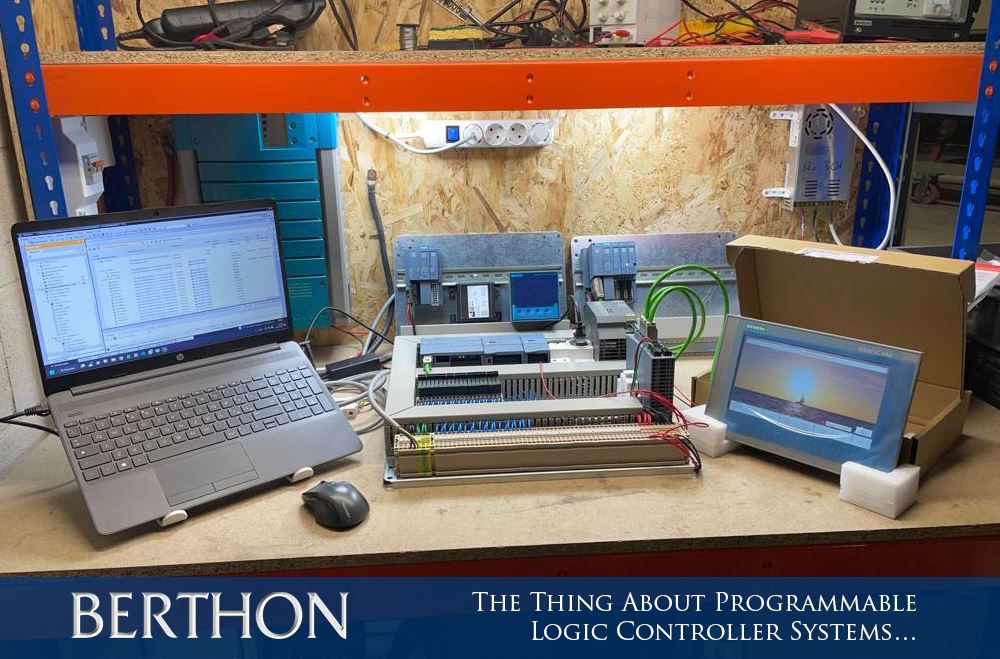

Berthon Spain’s Marine Electrician Leo Laterza has been a frequent sight in the workshop lately. Ensconced behind an array of breaker boards and sensors laid out in front of him. He is working on a Programmable Logic Controller system, or a PLC as it is known in the marine industry. Leo tells me that this Siemens PLC system for a 34m sailing yacht is far easier to program than previous systems he has worked on. However, Leo comes from 17 years’ experience in large industrial settings, where this kind of practice is much more common. You might be asking…

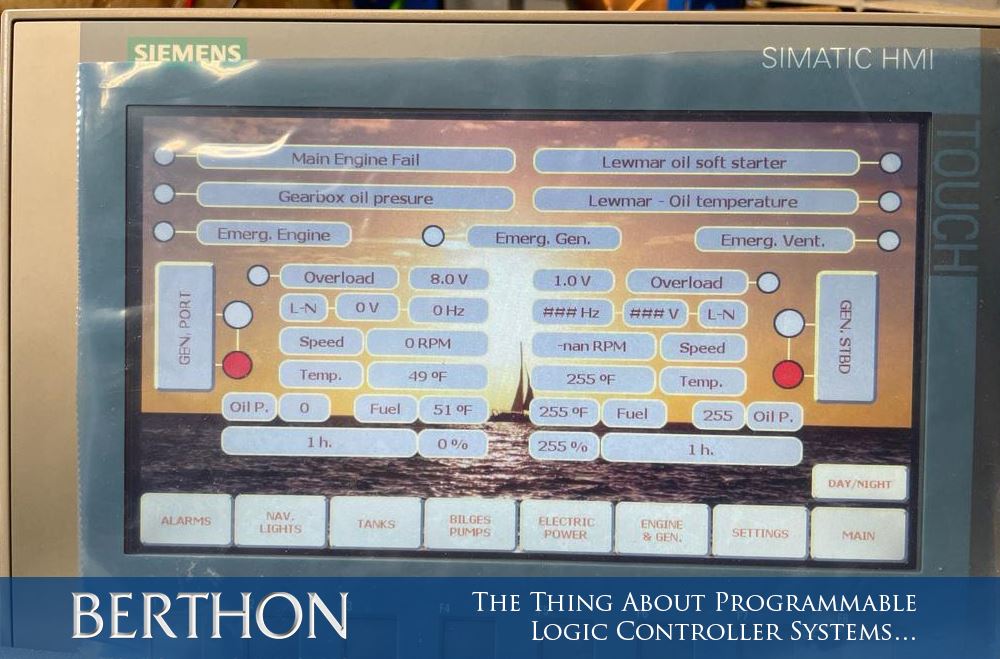

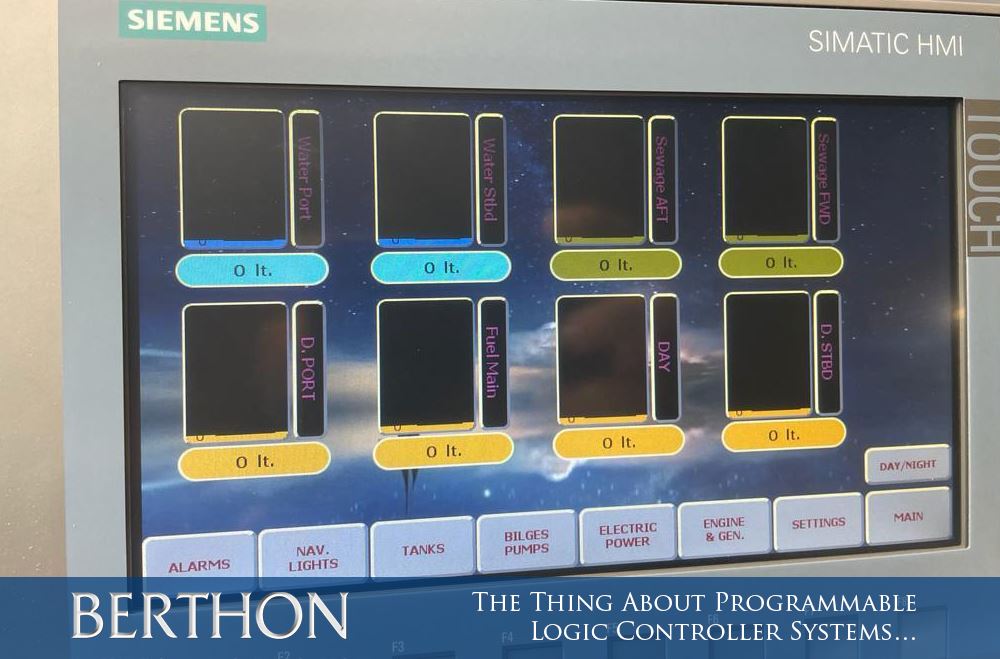

The main aim behind the installation of a Programmable Logic Controller is to allow the captain and crew to have access to a wide range of information, at their fingertips, and to stay in control if any changes occur.

The main breaker board, built with Schneider Electric components, will receive inputs in the form of a status update from sensors all around the yacht. There will be two types of input used here – digital and analogue.

Leo is setting up parameters for 2 different kinds of sensor, either a lineal transducer or sonar.

The calibration of these sensors is done in the workshop rather than in situ to make the process easier. For example, calibrating the level of each water tank sensor by filling the tanks and emptying them would not only be wasteful of the water, but time consuming as well. With the Weka tank sensor on the workbench, Leo is able to set parameters for the system by simply sliding the tank level sensor up and down.

Working alongside these sensor inputs, and all linked to the same control board, is the network. This communicates a different type of information input from different aspects of the yacht. This is how information regarding the shore power and generator are transferred to the PLC. From two Siemens control panels we will install, the crew will be able to monitor the voltage from the shore power, or the rpm, oil pressure and % power output from either generator.

The interface is working as a converter, where the inputs are being received in different languages, if you like, are all prepared to communicate on the same level.

The PLC can also decide outputs from the information it receives. For example, a high temperature input from the main engine will sound an alarm and initiate engine shut down. It can also be programmed to set up your desired navigation light selection i.e. sailing or under engine at night.

This whole system is completely new for this yacht, and all the installation will be done by Berthon Spain’s electrical team. In addition, a new range of B&G navigation equipment is being fitted throughout, and programmed alongside the PLC. The mechanical engineers at Berthon Spain will be undertaking the installation of two new Cummins Onan Marine Generators and the Cummins X15 main engine, which will be integral to the PLC system.

This project is part of a large refit on a Valdetarro 112, which has already taken up 100s of hours of hard work and planning from each department manager, with more work still to come! It will certainly be an impressive sight to behold once completed.

Watch this space for updates!

Contact Andrew Fairbrass on andrew.fairbrass@berthonspain.com.

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_gtag_UA_* | 1 minute | Google Analytics sets this cookie to store a unique user ID. |

| _gid | 1 day | Google Analytics sets this cookie to store information on how visitors use a website while also creating an analytics report of the website's performance. Some of the collected data includes the number of visitors, their source, and the pages they visit anonymously. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 6 months | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| VISITOR_PRIVACY_METADATA | 6 months | YouTube sets this cookie to store the user's cookie consent state for the current domain. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |